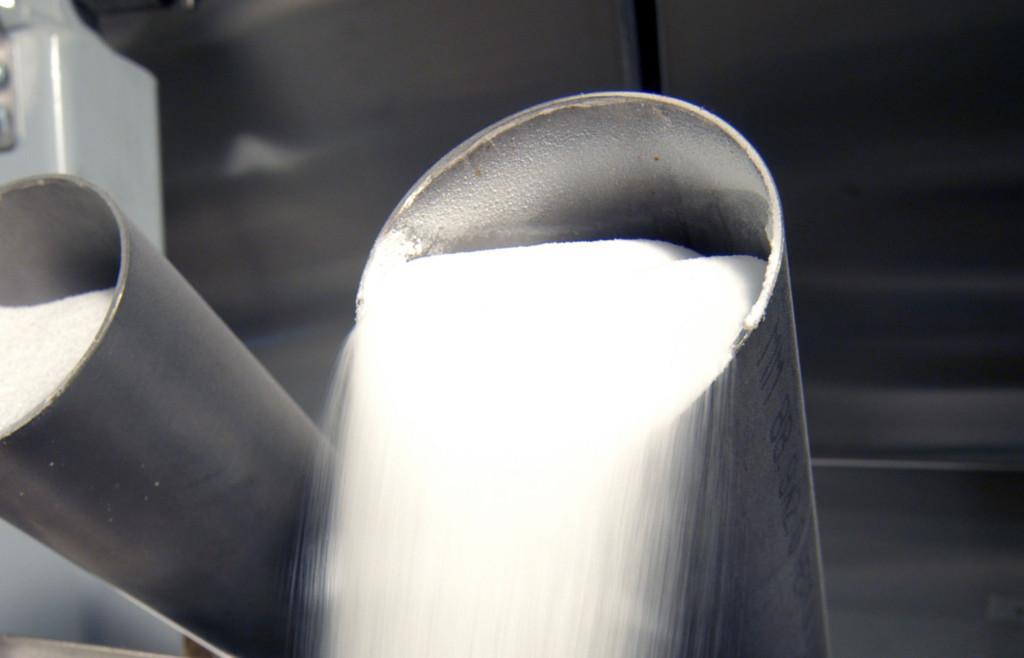

Powdea has obtained a patent for its new invention, which premixes the small ingredients to be dispensed according to the recipe before dispensing them into the actual mixer. Premixing is achieved by simultaneously dispensing the small ingredients in the recipe directly into a vacuum conveyor. Due to the simultaneous dosing, the small substances are premixed with each other before the actual mixing step. With the aid of the patented invention, the optimal quality of the final products is achieved, the multiple dosing speed and at the same time the dosing accuracy are significantly improved.

The problem is the optimal mixing of small ingredients

The development of the patented solution was initiated by the key need for bulk processes to ensure optimal quality of the final products by mixing the smallest components of the raw material mixtures as evenly as possible with other substances.

The problem of uniform mixing has previously been minimized e.g. by equipping the substance receiving container with a pre-mixing screw or by controlling the dosing process so that the substances are deposited in the receiving container in a certain way so that they mix well in the actual mixer.

The keys to the solution in simultaneous dosing

The patented invention came about when Powdea’s product development team sought to find a solution to the customer’s needs, which at the same time wanted to ensure premixing of small ingredients and achieve up to 30 batches per hour at a single dosing point.

It was clear from the outset that the keys to the solution were related to several simultaneous dosing processes and the acceleration of fine dosing, which is typically a bottleneck in capacity. The slowness of the dosing of small ingredients is due to the fact that there are several small ingredients to be dispensed in the product recipe and they have had to be dispensed slowly in order to optimize the dosing accuracy. Due to the vacuum air transfer typical of ingredient dosing, additional small substances have had to be dispensed one at a time, because starting two or more dispensations at the same time on a common conveyor would inevitably lead to congestion in the transmission line.

Realization

A key finding of the invention is the depressurization between the diluent dispensers and the vacuum transfer line, which allows for very accurate simultaneous dosing based on the weighing of all the dairy ingredients in the prescription. To control dosing, a completely new dosing algorithm was developed that calculates individual dosing parameters for each minor based on product recipe to start and stop dosing almost simultaneously from all tanks, while controlling the operation of the vacuum source based on dosing parameters and transfer pressure measurement.

The result is premixing and multiple dosing rates

Simultaneous weighed dosing of the small ingredients causes them to premix with each other already during transfer to the receiving tank, resulting in a homogeneous mixture of small ingredients that is evenly mixed into the dough mass. Due to the simultaneous dosing, the rate of dosing of the minor substance, which used to be a bottleneck, increases many times over.With the invention, our customers have reached up to 40 small amounts of dosing per hour and at the same time an accuracy of up to 5 g has been achieved for dosing results.

Take the industry forward and support our growth

“The patented invention is of enormous importance for the development of automated dosing processes for bulk materials. The benefits of premixing from simultaneous small ingredient dosing are undeniable regardless of industry. ” says Tuomo Kousa, CEO of Powdea. “The invention is also very important for our growth strategy. With it, we will improve our competitiveness and be better able to respond to fierce international competition. Thanks to the patent, we can now invest fully in marketing our solution,” Kousa continues.