Powdea’s product development has responded to the tightening dust requirements of the bakery and food industry and developed a fully dust-proof Anti-Dust ™ hood mechanism for its receiver hoppers.

Bakeries and food factories need help

For a couple of hundred years, it has been known that respiratory symptoms are a scourge for those working in bakeries and food factories that are handling powders. We have come to know these symptoms as asthma and runny nose. The diseases are due to special sensitization to flour dust and its various components, such as enzymes. Respiratory and ocular occupational symptoms have been reported to vary by approximately 10-30% in various studies. Asthma affects at least 5-10%. In Finland, the baker still has the highest risk of developing occupational asthma of all occupational groups (see H. Keskinen).

Reducing dust exposure in bakeries

Flour dust from bakeries (and food factories) is a problem for both workers and machinery and equipment. Not enough attention has been paid to reducing dust, although the harmfulness of flour dust has been known for centuries. Studies in recent years show that dust can be significantly reduced.

Exposure

Bakeries and food mills have several dusty working steps and the eight-hour HTP value for flour dust of 5 mg / m3 has been exceeded in many jobs. The dustiest jobs have been just do-it-yourself, do-it-yourself and do-it-yourself, as well as just do-it-yourself and working with a wire or perforated bread machine. In dough making, the average total dust content has been about 2 times the limit value for organic dust and, in addition, the results have varied widely. The highest concentrations have been several times higher than the HTP value. In addition, almost HTP levels have been measured in the weighing of enzymes and other additives.

Dough manufacturing

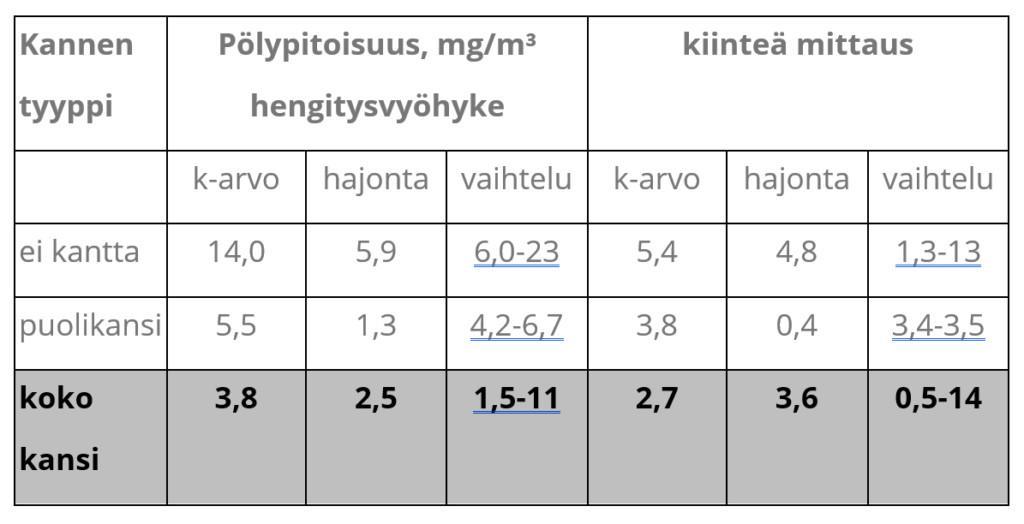

Even the partial enclosure of a dust source is found to affect the dust exposure of a bakery worker. The effect of dough bowl shields on dustiness is clear. The more closed the flour dispenser and the protective lid, the lower the dust concentration in the worker’s breathing zone. When using a closed system, the total dust content is less than 5 mg / m³. The most dust-free system is the dough bowl, which is completely closed and where the target removal is active during operation. Table 1 – Article of the National Institute of Occupational Health in bakeries on the implementation of the measure in dough production.

Table 1. Total dust concentrations in dough making (flour dispensing into bowl)

Powdea’s dust-tight hood mechanism prevents dust during flour dispensing

Powdea’s product development has responded to these problems and developed a dust-tight Anti-Dust hood mechanism for its flour receiver hoppers.

The automatic hood descends on the dough trolley under the control of pneumatic cylinders, closing it during emptying of the receiver hopper. After emptying the hopper, the hood rises to its upper position, so that the dough trolley can be removed from under the scale.

Advantages of a Powdea’s Anti-Dust™ receiver hoppers

- the k-value of the dust content is less than 5 mg / m3 in the making of the dough

- meet occupational safety regulations

- the amount of dust in the bakery premises is clearly reduced

- the need for cleaning is reduced, saving money

- employees’ job satisfaction improves

better productivity - lower staff turnover

- easier recruitment when working conditions are in order

Further information: Tuomo Kousa, M.Sc. (Eng.), CEO of Powdea