Challenging handling of oat flour

As a company specializing in the automatic dosing of ingredients, Powdea Technologies has gained extensive experience in the dispensing of oat flour in the food and bakery industries, where the production of oat-based products has grown exponentially.Based on its hands-on experience with the oat flour, it has turned out,that it is the most difficult powdery ingredient the company has ever faced. Thus, it’s controlled handling needs expertise in the discharge technology.

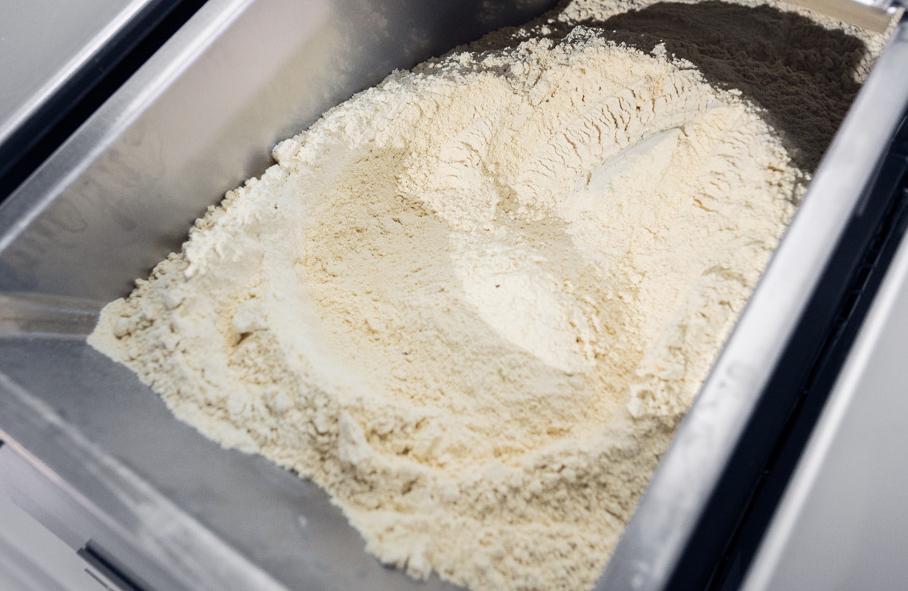

Oat flour is the most difficult ingredient to dose

Oat flour is completely different from other flours due to its 2-3 times fat content. The fine-grained and high-fat content of oat flour means that it has a very strong cohesive tendency from the point of view of powder handling. Concretely, it appears as an opportunity to shape it into balls that remain intact even when thrown. In terms of powder handling equipment, oat flour has a very strong vaulting effect, which makes it really difficult to feed it into a controlled and accurate process.

Fluidization technology as a solution for vaulting of oat flour

Powdea Technologies has more than 30 years of experience designing and implementing discharge technology for hundreds of different types of powder materials, and oat flour has proven to be the most demanding of all the powders they’ve encountered.

Based on their practical experiences with oat flour, the best method to dispense it out of the tanks is fluidization technology. Conventional screw and vibration solutions do not work. On the contrary, they aggravate the situation by further compacting the flour.

In silo dosing, the oat flour has been successfully discharged in a controlled manner in the process when the bottom of the silo is implemented as a fluidization cone. The Powdea fluidization cone allows perfect adjustment of fluidization power and settings, allowing optimal settings to be found for silos of all sizes.

Successful dosing of oat flour from silos in the Primula bakery

Successful dosing of oat flour from silos in the Primula bakery

Primula Bakery encountered difficulties in handling oats when the bakery increased its use of oat flour in its products and began using it as bulk deliveries. Primula already had a dosing system supplied by Powdea , which was designed to handle wheat and rye flour.

Problems were quickly identified with the introduction of oat flour: despite weighing tanks equipped with conventional fluidization equipment, the oat flour vaulted into the tanks and had to be transferred to manual dosing. Niko Puruskainen, Primula Bakery’s production manager, turned to Powdea, which began to map out solutions. It was decided to improve the performance of the bulk silo by replacing the previous silo with a new Powdea fluidization cone and the fluidization of the weighing tanks was enhanced with fluid plates designed by Powdea. Puruskainen is pleased with the solution: “Thanks to the fluidization solutions provided by Powdea, we were able to return the oat flour to automatic dosing.”

Successful dosing of oat flour from silos in the Primula bakery

Successful dosing of oat flour from silos in the Primula bakery