Project goals : Better realibility, tech support and NAV connection

The goals for the investment were to ensure the reliability for the existing dosing system’s controls, get a good online support for the system and connect to dosing system to Microsoft NAV erp-system. It was important that the modernisation such be done at such a manner that production stoppages were minimized.

No production stoppage in taking over

Powdea Technologies used it’s know-how of modernisation of other supplier’s dosing system and it’s clever ” parallel control” modernisation principle to update the automation with virtually no production stoppages at all.

New PLC control and recipe controller

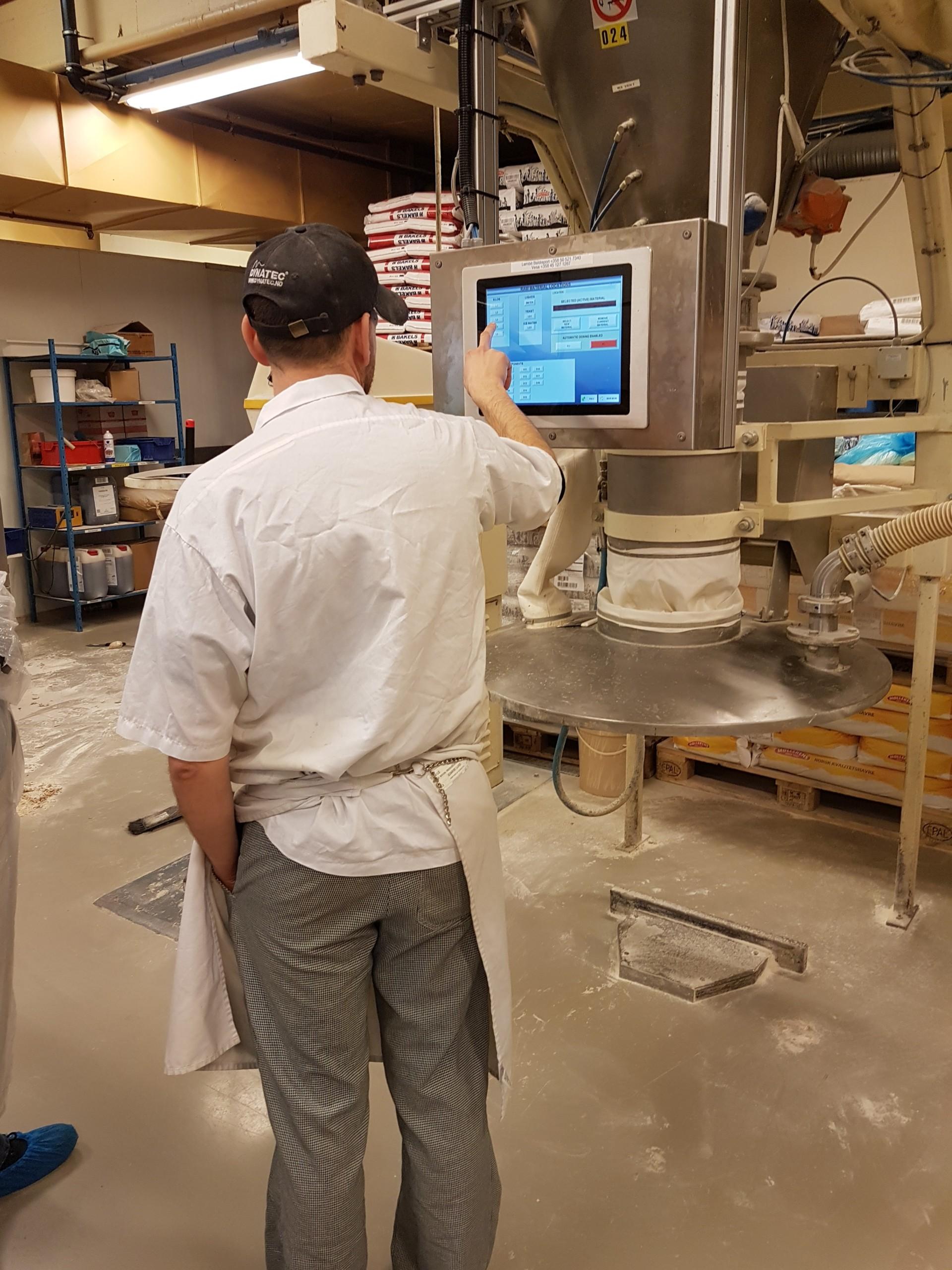

Powdea supplied a totally new PLC control that took over the control of the existing equipment and new added equipment. New 15″ touch screen operator panel replaced the old monitors.

Manual weighing also connected to NAV

New Smart Scales from Powdea replaced the old and not-functioning table scales. The new Smart Scales cales are conneted to PLC control enabling recipe-controlled dosing by a user-friendly grahphical-pointer view. The dosing results of manual weighings and stored to database for quality control.

Enhanced reliability to existing mechanical equipment

The mechanics of the existing equipment were enhanced by installing a ” smart-conveyor” functions to the pneumatic conveyor lines. This feature monitors the pneumatic conveyor constantly and adjusts conveying automatically if there is abnormalities during conveying phase.

NAV connection for recipe and quality control

The new control system was successfully connected to Baker Brun’s NAV erp system. NAV system holds the latest versions of recipes and sends the recipe information to PLC’s recipe controller. The dosing results and the amounts of used ingredient are stored direclty to NAV’s database for quality control and inredient inventory.

Successful start-up due to good preparation

The taking over was done in close co-operation between Powdea and Baker Brun. Powdea Technologies supplied the new automation components well before actual start-up to make sure all installations by Baker Brun were ready in time for taking over. The NAV integration was prepared carefully in Powdea’s simulation environment, where data trasfer could be tested beforehand. This procedude ensured a smooth intergration at start-to NAV.

” We are extremely happy that Baker Brun selected us as the supplier. We had a good project in NAV integration just completed in Finland and we knew how to update Baker Brun’s dosing system successfully, even though it was not originally supplied by us. We put our best effort for this project and I’m pleased for the results we delivered to Baker Brun” -Tuomo Kousa, CEO of Powdea Technologies Oy