Lietuvos kepėjas is one of the leading suppliers of fresh and frozen bread and bakery products in Lithuania. Their factory in Kaunas was built in 1991. It had several stages of major changes since then. After the last modernization in early 2014 it is probably the most modern factory in Baltic states, capable to produce up to 100 tons of baked goods a day. Powdea Technologies supplied a complete recipe controlled dosing system for automatization of the ingredient dosing to mixer.

Modernisation and integration of existing silos

Powdea’s delivery included modernization of the customer’s existing silos. Powdea improved the fluidisation system by connecting the air supply to the compressed air line and taking the fluidisation valves into it’s control. Powdea re-engineered the filling pipes and filtration systems of the silos. The silos were equipped with diverting pipe and new rotary locks that allowed the conveying of the main ingredients from silos to new production line without reducing the capacity of existing lines.

Small and minor ingredient dosing automated with Powdermatic™ IB200 unit

The biggest benefit of the investment was achieved by fully automatic minor and small ingredient dosing. Thanks to Powdeas Powdermatic™ iB200 unit, all minor and small ingredients, such as salt, sugar, improvers are dosed fully automatically straight to the dough mixer. The recipe controlled ingredient dosing system consists of Powdermatic™IB200 ingredient dosing unit with 7 dosing hoppers for small ingredients and BigBags.

Automatic liquid dosing

The dosing of water and oil is also automatic with Powder Technic’s Watermatic™ and Fluidmatic™DUO dosing units.

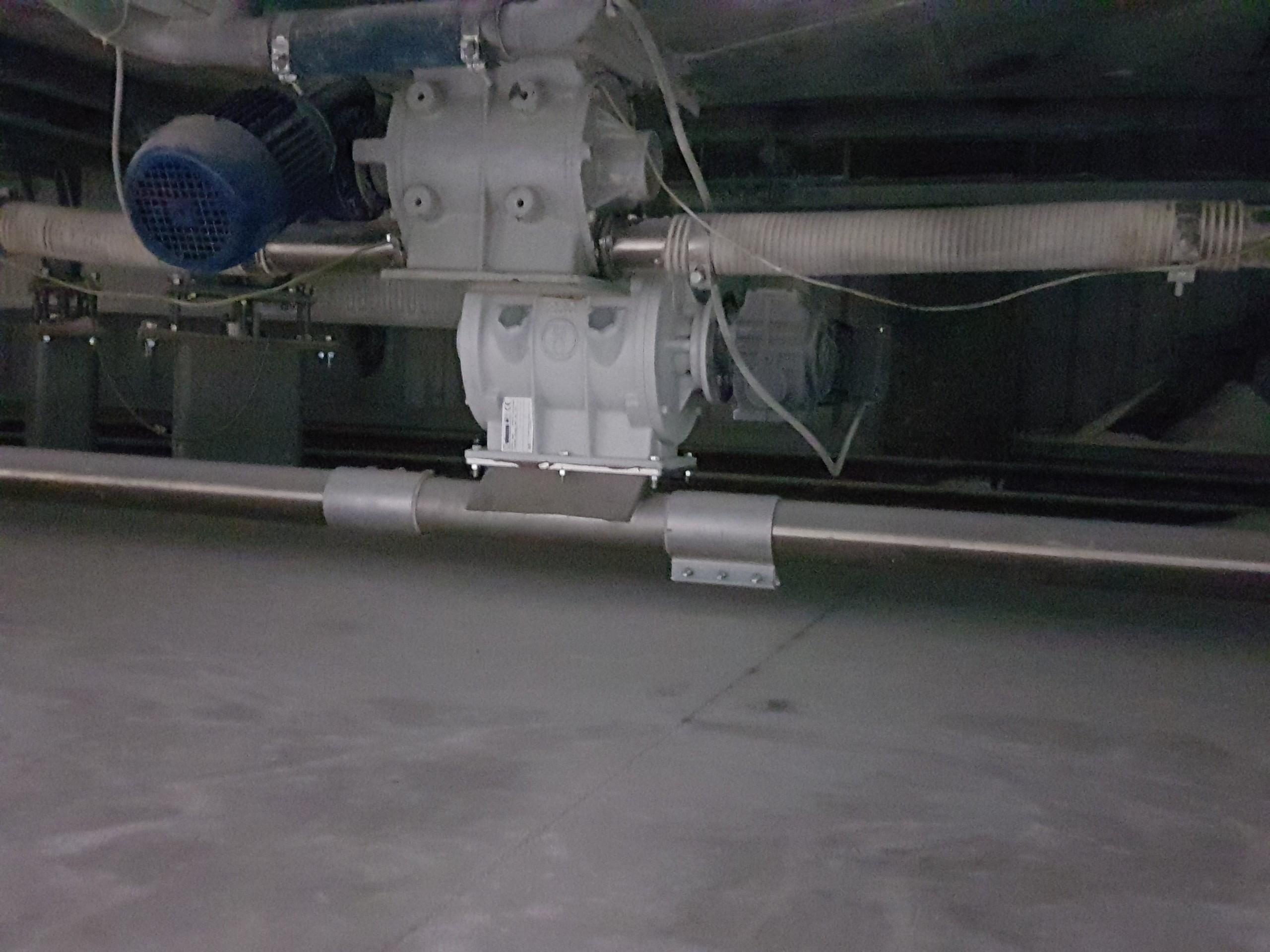

New Powdea Sure-Flow™ vacuum conveyor lines transport ingredients to the mixer

The delivery includes new pneumatic conveyor lines from customer’s 5 indoor silos and Powdermatic unit to the new 200 l receiver hopper, that was placed on the top floor above the automatic mixer. Once the carefully weighed mix of ingredients is ready in the receiver hopper, it will be dropped to the San Cassiano Genesis automatic mixer when the mixer sends signal to the Powdea’s system.

Manual dosing connected to the quality control

The manual weighing and dosing of micro ingredients and ingredients outside automatic dosing is done be Powder Technic’s Smart Scale that is linked to Recipe-dosing software.

Powdea’s recipe controller controls and monitors the dosing of ingredients

In accordance with the product recipes, the recipe dosing system doses six 300-litre raw ingredient batches an hour. The active dosing accuracy maintenance automation monitors dosing accuracies and raw ingredient stock levels. Dosing actions and raw ingredient consumption reports for a desired time period are saved in the system and can be used for a variety of purposes.

Lietuvos kepėjas

In English, our name means “Baker of Lithuania”. It obliges us, and the bread for us means much more than just a product. The company dedicates a significant part of its income to charity and education, and with partners from other Baltic States Latvijas Maiznieks (“Baker of Latvia”) and Eesti Pagar (“Baker of Estonia”) participates in the project, which aims to preserve and enhance the national heritage of bread. It is vividly named “Baltic way of bread”. read more..