The Latvian industrial bakery Latvijas Maiznieks has chosen Powdea as its supplier of dispensing systems. The delivery includes the automatic dosing of the dry and liquid ingredients needed for the dough. Powdea makes the delivery in cooperation with Leipurin, which is in the Powdea bakery market in Latvia.

New outdoor silos for flour

Integration of customer liquid tanks into automatic dosing

Delivery includes automatic dosing of water, oil and liquid yeast. Powder Technic integrates the customer’s oil and liquid yeast tanks into its PLC controllers.

Transfer of flour from silos with Sure-Flow ™ vacuum conveyors

The delivery includes new pneumatic conveyor lines from the new outdoor silos to the new 200-liter receiving tank.

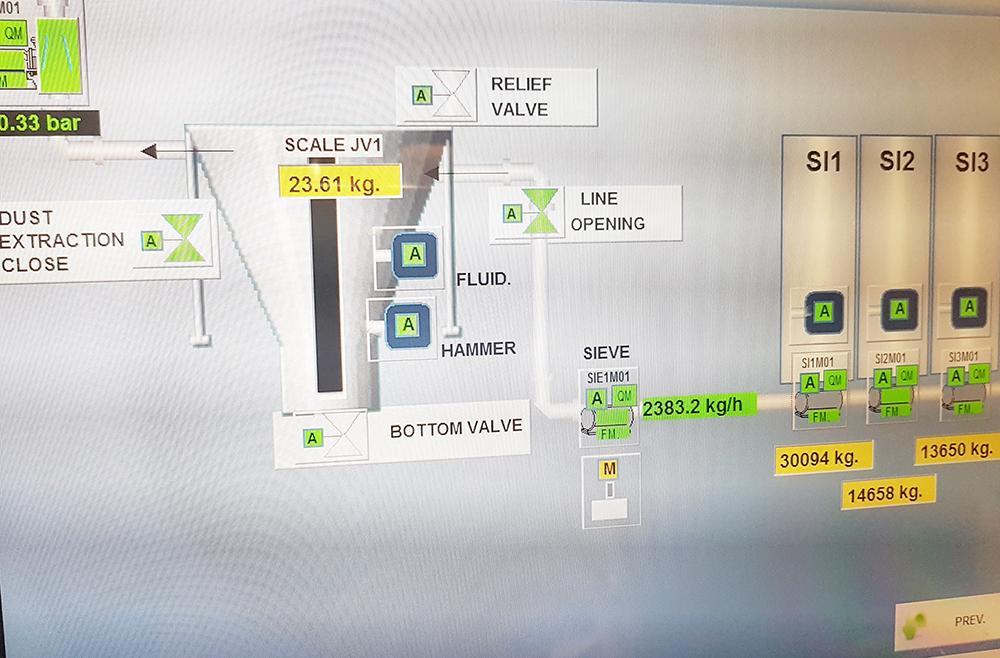

Flour screening with a Powdean Pneumatic Screen

The aim was to ensure the high quality of the customer’s products by equipping the vacuum conveyor line with a screen and a magnet. Powdea fulfilled the customer’s need with its own Powdea Pneumatic Screen, which is able to screen the main raw materials over 3000 kg / h. The screen is equipped with a flame arrester that meets the requirements of the Atex Directive. A strong permanent magnet installed as part of the transmission line further ensures the purity of the raw materials by removing the magnetic particles from the material flow.

The smart scale guarantees accurate manual weighing

Manual weighing and dispensing of ingredients outside of automatic dispensing is performed on the Powdea Smart Scale, which is linked to the Prescription Dispensing Software provided by Powdea. The names and quantities of the substances to be weighed manually will automatically appear on the Smart Scale screen when the automatic dosing starts. During this, the dough maker weighs the small ingredients accurately according to the recipe into a transfer box, which is finally emptied into a mixer.

Dosage according to the prescription

The prescription dispensing system dispenses six batches of 300 liters of raw material per hour according to product recipes. Active dosing accuracy maintenance automation monitors dosing accuracy and raw material inventory. Dosing events and raw material consumption reports for the desired period are stored in the system and can be used for quality control.

All goals were achieved on time “

Mihails Valovs, Technical Director of Latvijas Maiznieks, is pleased with Powdea’s delivery: “We achieved all the set goals on time. No changes or improvements were needed.”

Flexible service from Powdea

The project was implemented in cooperation with the customer, so that the customer was responsible for the equipment installations. Valovs is pleased with the technical support he received: “Emails and calls were not left unanswered. The answers were always informative. Well-made drawings help a lot during installation,” says Valovs.

Latvijas Maizniks

With every meal, all over Latvia – the bread of bakers!

An excellent mix of the best traditions and the latest technology – this is the secret of the delicious bread of Latvijas Maiznieks. The bakery, which has been operating continuously since 1968, has undergone countless changes in its history and has become one of the largest bakeries in Latvia.