Powdea EasyCleanFeeder™ washable powder dispenser for food factories

Thanks to the Powdea Fluidi™ technology, it is also suitable for non-flowing powders

With Powdea Loss-in-Weight controller or volumetric dosing

Below you can see some of our ready-made solutions for complete industrial bakery line systems. We can also customise a system to meet the unique needs of your production and the high demands of the food industry.

Powdea EasyCleanFeeder™ washable powder dispenser for food factories

Thanks to the Powdea Fluidi™ technology, it is also suitable for non-flowing powders

With Powdea Loss-in-Weight controller or volumetric dosing

connect Empty the small bags ergonomically and dust-free to the pneumatic transfer line

Patented AntiDust™ technology, which enables dust-free flattening of the empty sack directly into the waste container

Specially designed for handling dusty powders

Powdea Feeder is designed for accurate batch dosing of powders based on weighing

Thanks to the Fluidi™ technology, it is also suitable for poorly or non-flowing powders

Plug&Dose™-readiness when equipped with a Powdea batch controller

Hygienic floor scale that rises from the floor with an automated lifting mechanism

Developed especially for baking dough bowls

Integrates seamlessly with Powdea dispensing systems and software

Accurately dispenses powdery or granular substances into small packages

Thanks to the modern PLC+Servo control, the device is extremely accurate and reliable in its operation

PC connectivity for quality control

Powdea GraviFeeder™ is a solution for weighed dosing of powders

Thanks to the Fluidi™ technology, it is also suitable for poorly flowing powders

Equipped Powdea Loss-in-Weight or Batch controller

Dispense the small ingredients directly into the pot, weighed exactly according to the recipe

Free up your dough maker from flour dispensing for more productive work

Save 3-5% on bakery raw material costs through more efficient use of raw materials and reduced waste

Dispense the small ingredients directly into the dough bowl, weighed exactly according to the recipe

Free up your dough maker from flour dispensing for more productive work

Save 3-5% on bakery raw material costs through more efficient use of raw materials and reduced waste

Dispense the small ingredients directly into the dough bowl, weighed exactly according to the recipe

Free up your dough maker from flour dispensing for more productive work

Save 3-5% on bakery raw material costs through more efficient use of raw materials and reduced waste

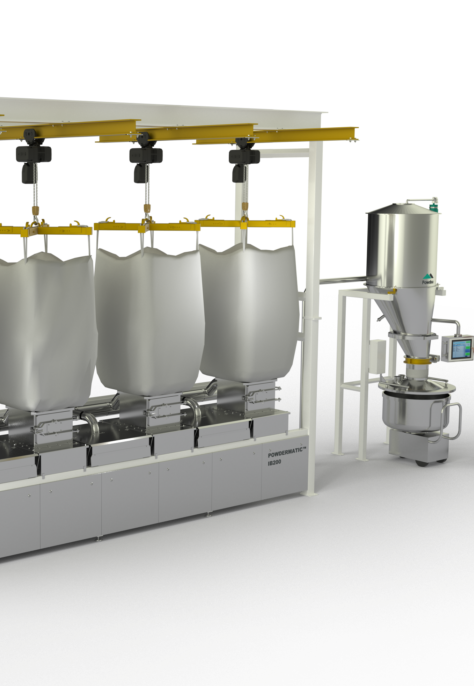

The fastest dispensing device on the market for dispensing powder mixtures into collection boxes

Patented Multi-Dose technology that allows more than 100 boxes to be filled per hour

Suitable for dispensing almost all powder and granular substances

Reduce your labor costs by letting Powdermatic Lite S handle the dosing

At the touch of a button, Powdermatic Lite S dispenses small ingredients into a transfer box according to a recipe

Suitable for dispensing almost all powder and granular substances

Monitors manual weighing and saves weighing events for quality monitoring

Digitize your recipes with the Dough Master ™ program and make sure you always have the latest recipes in production

Read dosing reports on your laptop of smart device

Recipe-controlled manual dispensing of small ingredients into boxes

Tolerance control and proportional functions

Dosing reports are automatically saved for traceability

Use our product configurator to make your hardware just right for your needs and send a request for quotation.

© 2025 Powdea Technologies Oy