Precise thermostatic adjustment

80 recipe memory

Stainless steel casing

Easy installation

Powdea Connectivity ready

Below you can see some of our ready-made solutions for complete industrial bakery line systems. We can also customise a system to meet the unique needs of your production and the high demands of the food industry.

Precise thermostatic adjustment

80 recipe memory

Stainless steel casing

Easy installation

Powdea Connectivity ready

Automatic water temperature control, 3 inputs

99 recipe memory

Stainless steel casing

Easy installation

Powdea Connectivity ready

Powdea EasyCleanFeeder™ washable powder dispenser for food factories

Thanks to the Powdea Fluidi™ technology, it is also suitable for non-flowing powders

With Powdea Loss-in-Weight controller or volumetric dosing

connect Empty the small bags ergonomically and dust-free to the pneumatic transfer line

Patented AntiDust™ technology, which enables dust-free flattening of the empty sack directly into the waste container

Specially designed for handling dusty powders

Powdea Feeder is designed for accurate batch dosing of powders based on weighing

Thanks to the Fluidi™ technology, it is also suitable for poorly or non-flowing powders

Plug&Dose™-readiness when equipped with a Powdea batch controller

Hygienic floor scale that rises from the floor with an automated lifting mechanism

Developed especially for baking dough bowls

Integrates seamlessly with Powdea dispensing systems and software

Suitable for dusts with a dust explosion hazard

Automatic cleaning of filter elements

Independently functioning or seamlessly integrated into Powdea’s dosing equipment

Powdea’s PowderHow guarantees operational reliability

Elimination of loss and wastage

Efficient process with patented premix

Up-to-date production information and 24/7 remote monitoring

Elimination of loss and wastage

Efficient process with patented premix

Up-to-date production information and 24/7 remote monitoring

Control the dough maker with a digitized recipe

Track and manage the profitability factor of dough production with a digitized recipe

Optimize and design the production process

Ensure the correct order of intake of ingredients in the correct bowl

Ensure your dough mixes according to the recipe

It guards the rest time of your dough and tells the baker when the dough is ready for the next step

Shows the amount of ingredient in the silo on the web page

Enables automatic filling of your silo thanks to an automatic low limit alarm

Easily retrofitted to all silos with weighing equipment

Controls the dough preparation processes

Developed in collaboration with bakers to make it very easy to use and suitable for the bakery

With OnlineCare ™ remote management, help is close to you 24/7

Developed for accurate continuous dosing of powdery substances

Easy to use

Remote control

Developed for accurate batch dosing of powdery substances

Easy to use

Remote control

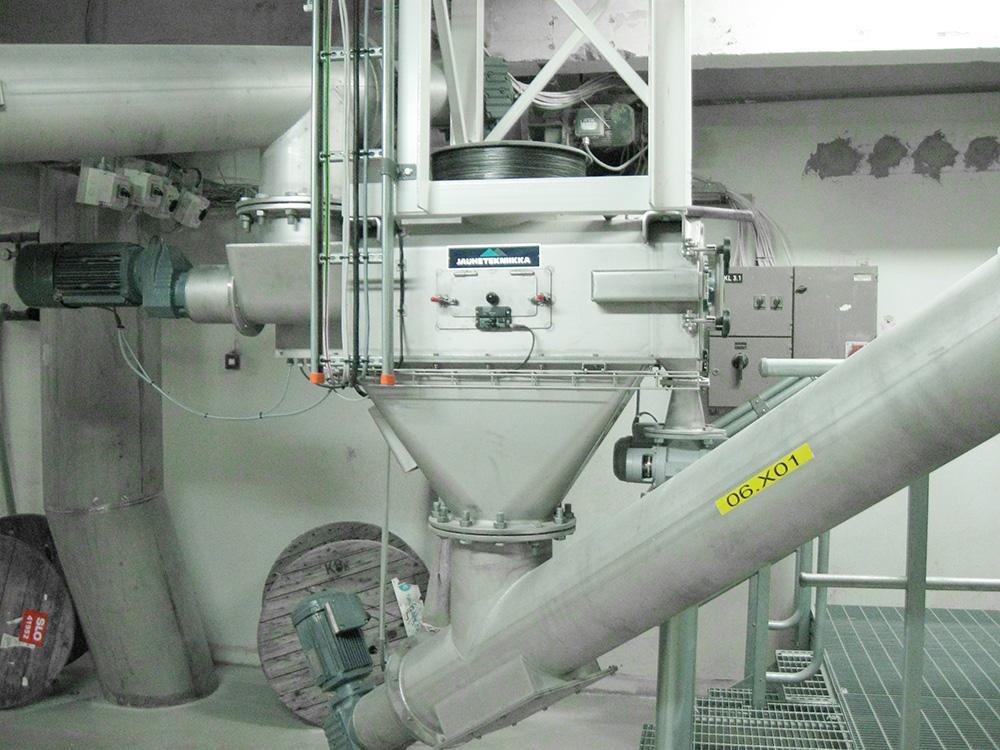

Screening takes place as part of pneumatic transport

Removes debris from powders, Crush lumps and hardened powder

The screening part is made of durable perforated plate

Suitable for screening explosive powders

Suitable for screening explosive powders

Removes debris from powders and crushes lumps and hardened powder

The screening part is made of durable perforated plate

Removes debris from powders

Crush lumps and hardened powder

The screening part is made of durable perforated plate

Complies with occupational safety regulations

Adjustable attachment points

Suitable for all large sacks equipped with lifting loops

Especially suitable for storing of wheat and rye flour in bakeries

Reliable operation: equipped with Powdea Fluidi™ technology

PowderHow: silo equipment selected based on powder’s properties

Economical compared to stainless steel silos

A high-quality solution especially for powders in the food industry

Does not condense moisture

No vaulting: equipped with Powdea Fluidi™ technology

PowderHow: silo equipment selected based on the properties of the powder

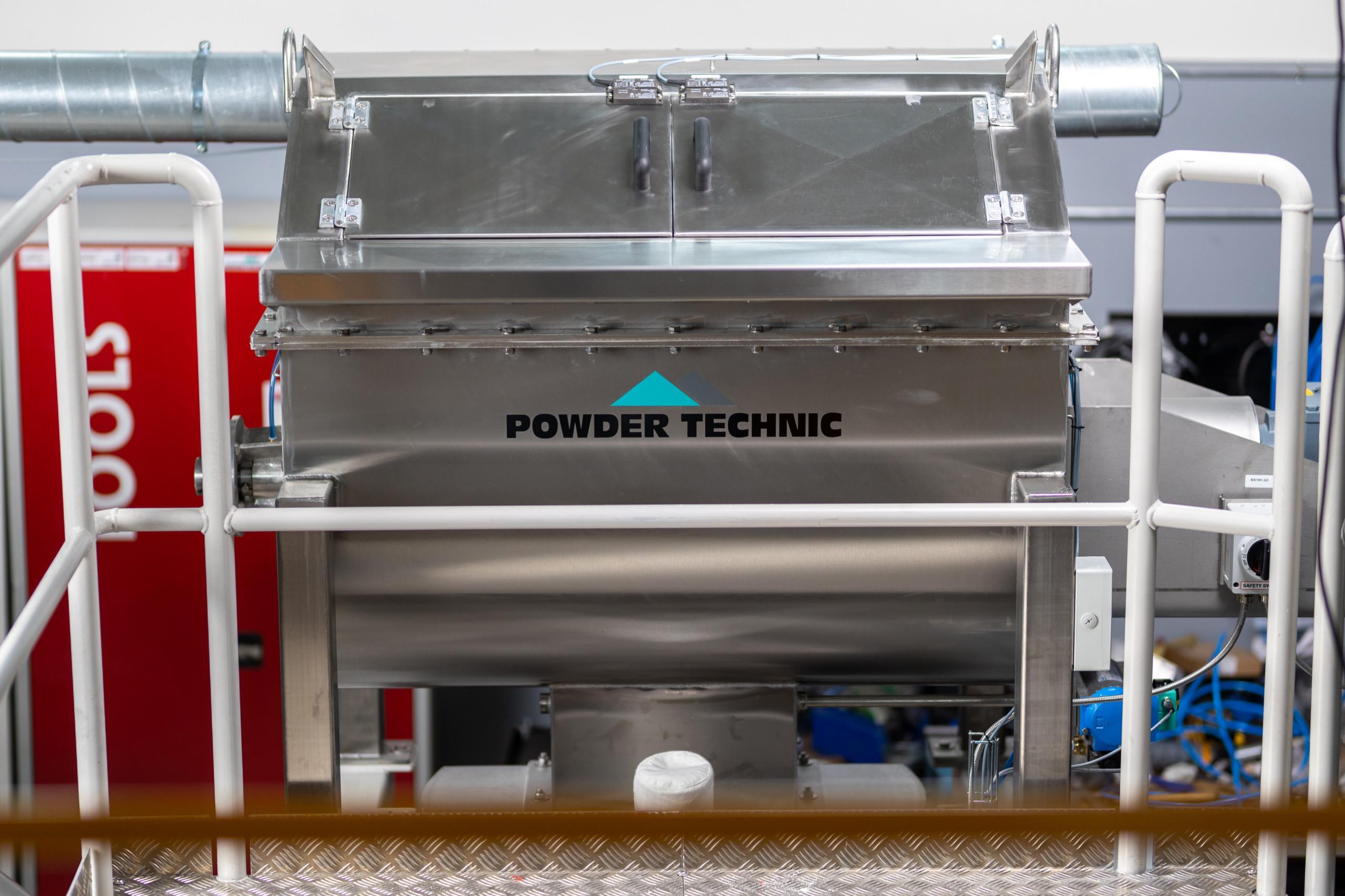

Quick mix

Blender type: ribbon Blender

Easy to fill and clean thanks to the large hatches

Dispenses the liquids automatically into your dough from the IBC container

You get a consistent dough quality with accurate dosing based on weighing and logic control

Automatic filling of the dosing container from the filling container on top

Stand-alone solution or can be connected to Powdea dosing system

Automatically dispenses liquids into your dough directly from the IBC container

You get a consistent dough quality with accurate dosing based on weighing and logic control

stand-alone system or connected to powdea dosing system

Customized as needed

Excellent performance and speed

Automatic cleaning

Easy control thanks to the touch screen and remote interface

Economical water dispenser with volume measurement and temperature control

Good accuracy: – / + 1% in volume and 1.5 degrees

Plastic casing

Easy installation

Powdean Connectivity valmius

Only measurement only without temperature control

Good accuracy: – / + 1%

Plastic case

Easy installation

Powdea Connectivity ready

Automatic water temperature control

The 10 “TFT color screen ensures easy and intuitive usability

Maximum dosing accuracy thanks to self-learning dosing

Remote control for settings and online support

Powdea Connectivity ready

Automatic water temperature control, 3 inputs

99 recipe memory

Stainless steel casing

Easy installation

Powdea Connectivity ready

Good thermostatic control

1 recipe memory

Plastic case

Easy installation

Powdea Connectivity ready

Precise thermostatic adjustment

80 recipe memory

Stainless steel casing

Easy installation

Powdea Connectivity ready

Domix water dispensers for artisan bakeries with thermostat control

Tridomix water dispensers for industrial bakeries with automatic temperature control

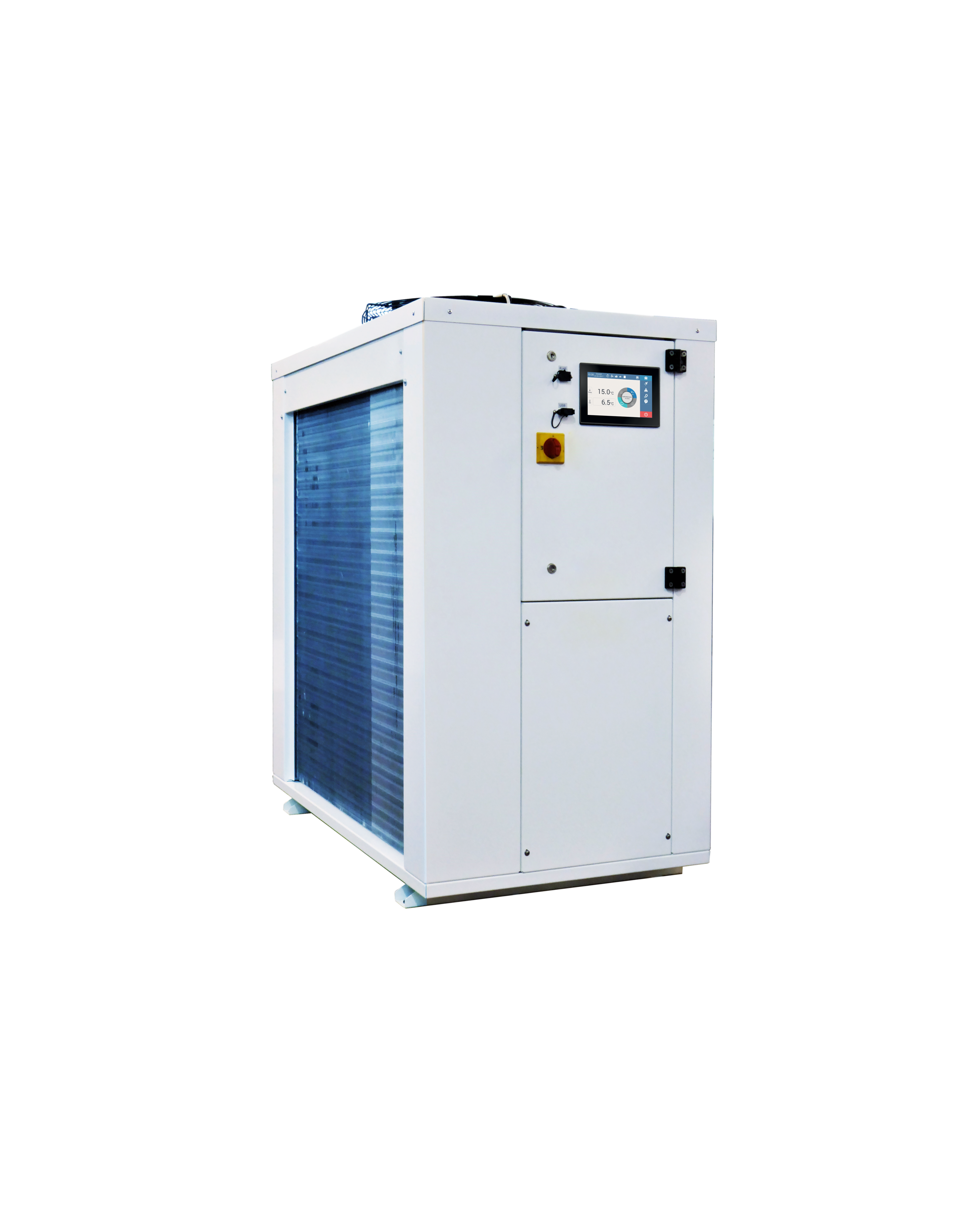

Chiller water coolers

Separately or connected to Powdea dispensing equipment and control system

Effective target dust extraction to max. two extraction points

Automatic cleaning of filter elements

Stand-alone or seamless integration with Powdea dosing equipment

Material handling specialist PowderHow guarantees operational reliability

Effective target dust extraction of one extraction point

The most popular model

Stand-Alone or seamlessly integrates with Powdea’s dosing equipment

Material handling specialist PowderHow guarantees operational reliability

Effective target dust extraction to one extraction point

Automatic cleaning of filter elements

Stand-alone or seamless integration with Powdea dosing equipment

Material handling specialist PowderHow guarantees operational reliability

Accurately dispenses powdery or granular substances into small packages

Thanks to the modern PLC+Servo control, the device is extremely accurate and reliable in its operation

PC connectivity for quality control

Powdea GraviFeeder™ is a solution for weighed dosing of powders

Thanks to the Fluidi™ technology, it is also suitable for poorly flowing powders

Equipped Powdea Loss-in-Weight or Batch controller

Elimination of loss and wastage

Efficient process with patented premixing

Up-to-date production information and 24/7 remote monitoring

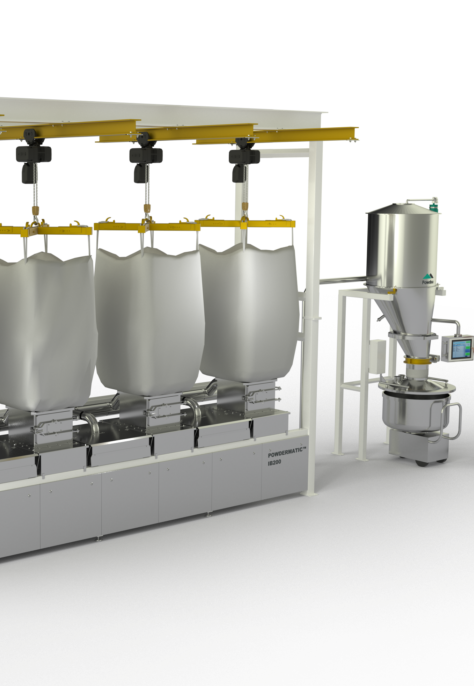

Automated and inexpensive delivery of one or more agents

Automate your flour dispensing at low cost with large bag dispensing or small-space Trevirasilo

Our step-by-step model enables increase of automation level in steps

Dispense the small ingredients directly into the pot, weighed exactly according to the recipe

Free up your dough maker from flour dispensing for more productive work

Save 3-5% on bakery raw material costs through more efficient use of raw materials and reduced waste

Dispense the small ingredients directly into the dough bowl, weighed exactly according to the recipe

Free up your dough maker from flour dispensing for more productive work

Save 3-5% on bakery raw material costs through more efficient use of raw materials and reduced waste

Dispense the small ingredients directly into the dough bowl, weighed exactly according to the recipe

Free up your dough maker from flour dispensing for more productive work

Save 3-5% on bakery raw material costs through more efficient use of raw materials and reduced waste

The fastest dispensing device on the market for dispensing powder mixtures into collection boxes

Patented Multi-Dose technology that allows more than 100 boxes to be filled per hour

Suitable for dispensing almost all powder and granular substances

Completely dustproof powder transfer

particularly suitable for transfers of less than 50 meters

Easy to install

Does not use compressed air to make vacuum

Suitable for small transfer capacities (100..1000 kg/h )

They are well suited for medium and long (10–50 m) conveying distances

Easy to install

Can be easily installed even in tight spaces

Suitable for various transfer capacities from 1000 to 8.000 kg /h

Food-Safe:suitable for all food ingredients: wheat flour, rye flour, oat flour, sugar etc.

Can be easily retrofitted

Reduce your labor costs by letting Powdermatic Lite S handle the dosing

At the touch of a button, Powdermatic Lite S dispenses small ingredients into a transfer box according to a recipe

Suitable for dispensing almost all powder and granular substances

Monitors manual weighing and saves weighing events for quality monitoring

Digitize your recipes with the Dough Master ™ program and make sure you always have the latest recipes in production

Read dosing reports on your laptop of smart device

Recipe-controlled manual dispensing of small ingredients into boxes

Tolerance control and proportional functions

Dosing reports are automatically saved for traceability

Use our product configurator to make your hardware just right for your needs and send a request for quotation.

© 2025 Powdea Technologies Oy